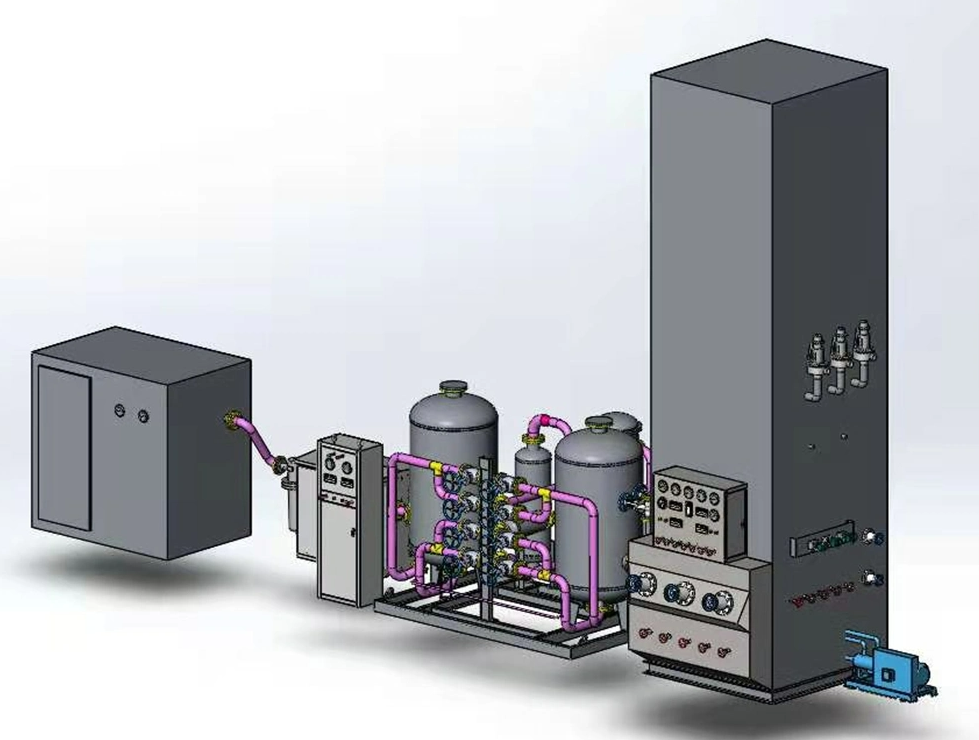

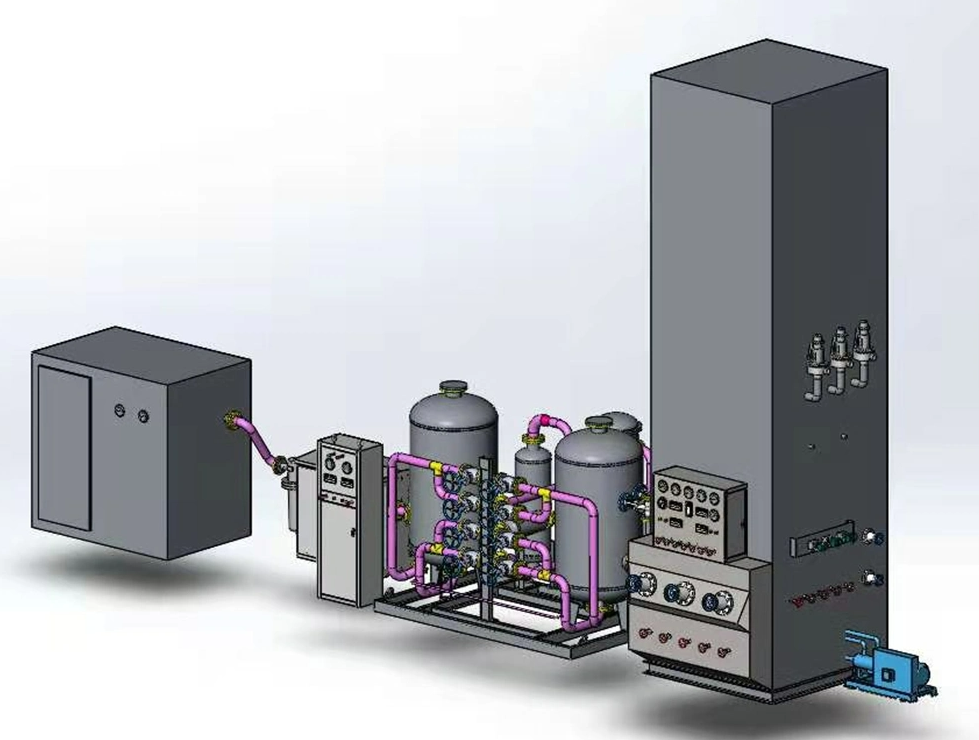

Nitrogen generator is a device that uses compressed air as raw material and uses carbon molecular sieve adsorbent to selectively adsorb nitrogen and oxygen. There are three types of nitrogen generators used in industry. Technically speaking, nitrogen generator is a nitrogen equipment designed and manufactured according to pressure swing adsorption technology. The nitrogen generator uses CMS as the adsorbent, and adopts the principle of pressure swing adsorption (PSA) to separate air at room temperature to prepare high-purity nitrogen. Generally, two adsorption towers are connected in parallel, and the imported PLC controls the automatic operation of the imported pneumatic valve. Alternately carry out pressure adsorption and decompression regeneration to complete the separation of nitrogen and oxygen to obtain the required high-purity nitrogen. In terms of work flow, the nitrogen generator is compressed by the compressor and enters the cold dryer for freeze drying to meet the dew point requirements of the raw air pressure adsorption nitrogen control system. The oil and water in the raw air are then removed through a filter into an air buffer tank to reduce pressure fluctuations. Finally, the pressure valve is adjusted according to the rated working pressure and sent to two adsorbents (containing carbon molecular sieves), where the air is separated to obtain nitrogen. The nitrogen generator has the advantages of convenient nitrogen production, fast speed, less land occupation, less investment and less investment. Nitrogen production is more economical than other nitrogen supply methods. Moreover, the PSA process is a simple and convenient method for nitrogen production, using air as the raw material, with low operating cost, low energy consumption and high efficiency. With the advancement of automation technology, the nitrogen generator can realize automatic operation according to the design of mechatronics, that is, the imported PLC controls the automatic operation, and the purity of the nitrogen flow and pressure can be adjusted and continuously displayed to realize unattended operation. In the pharmaceutical industry, high-purity nitrogen is required. Nitrogen and other pharmaceutically acceptable nitrogen equipment, because the international pharmaceutical industry GMP standards, or different standards for the parts in contact with liquid drugs are made of stainless steel and require sterilization, the unit requires stainless steel, the nitrogen outlet filtration for the sterilization equipment installation device.

Kunpeng has Air Separation Plants, PSA Oxygen Generator, Liquid Oxygen Plant, Liquid Nitrogen Plant, Medical Oxygen Plant, PSA Nitrogen & Liquid Nitrogen Plant and so on. If you need, please don't hesitate to contact us.