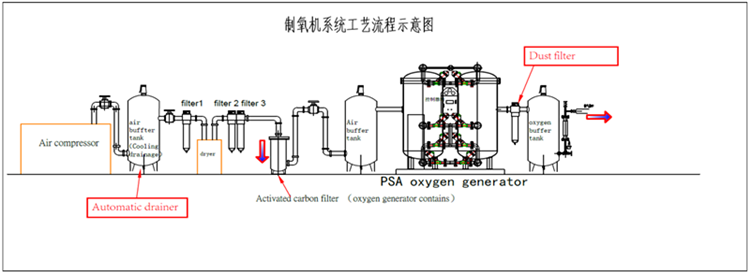

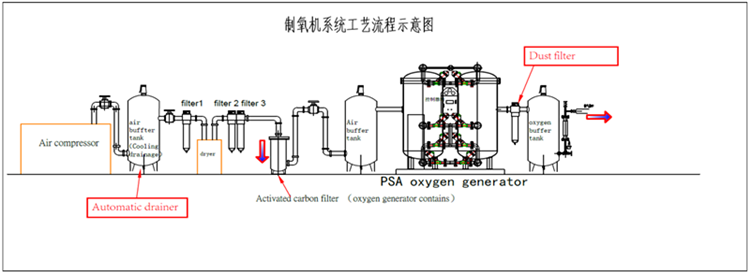

Main technical features of explosion-proof nitrogen generator: The explosion-proof industrial nitrogen generator uses air as the raw material, carbon molecular sieve as the adsorbent, using the principle of pressure swing adsorption, and the method of separating nitrogen and oxygen by the selective adsorption of oxygen and nitrogen by carbon molecular sieve, commonly known as PSA nitrogen production. The structure design of the adsorber used in the nitrogen generator has its own unique features. The upper and lower parts of the adsorber have reliable filtering devices, and a special pressing device is designed, so that the adsorber does not need to add molecular sieves during use. Due to the unique structural design of the adsorber, the distribution of the air flow is quite uniform, thus ensuring the excellent performance of the machine to a large extent.  Main technical performance of explosion-proof industrial nitrogen generator: 1. The whole machine is explosion-proof: explosion-proof industrial nitrogen generator, the whole machine can be manufactured not only as underground mobile type, but also as ground fixed type or ground mobile type. 2. Small size, easy installation and movement: The explosion-proof industrial nitrogen generator can be easily moved to any nitrogen injection site, especially suitable for random use in multiple working faces or mines. 3. Reliable performance and simple operation: only the air compressor section has moving parts, other parts are static work, which can ensure long-term operation and stable system performance. 4. Comprehensive protection: The explosion-proof industrial nitrogen generator has various protection functions such as over-temperature and over-pressure, and the main technical parameters are continuously displayed online.

Main technical performance of explosion-proof industrial nitrogen generator: 1. The whole machine is explosion-proof: explosion-proof industrial nitrogen generator, the whole machine can be manufactured not only as underground mobile type, but also as ground fixed type or ground mobile type. 2. Small size, easy installation and movement: The explosion-proof industrial nitrogen generator can be easily moved to any nitrogen injection site, especially suitable for random use in multiple working faces or mines. 3. Reliable performance and simple operation: only the air compressor section has moving parts, other parts are static work, which can ensure long-term operation and stable system performance. 4. Comprehensive protection: The explosion-proof industrial nitrogen generator has various protection functions such as over-temperature and over-pressure, and the main technical parameters are continuously displayed online. 5. Adjustable nitrogen production: increase or decrease the number of membrane modules, the nitrogen production can be changed.